Intraocular lenses and ophthalmic devices such as contact lenses, corneal inlays or onlays, and glaucoma treating devices are our primary focus at Ocular Technology Inc. Our passion and expertise truly lies in helping the world see in new and innovative ways.

We have over thirty years of experience in the field and offer a wide array of services that directly support the development and manufacturing of these types of devices, and more.

IOL & Small Lens Services Offered

Need assistance with your project?

Our IOL services save you time and money.

Our small and micro lens technologies

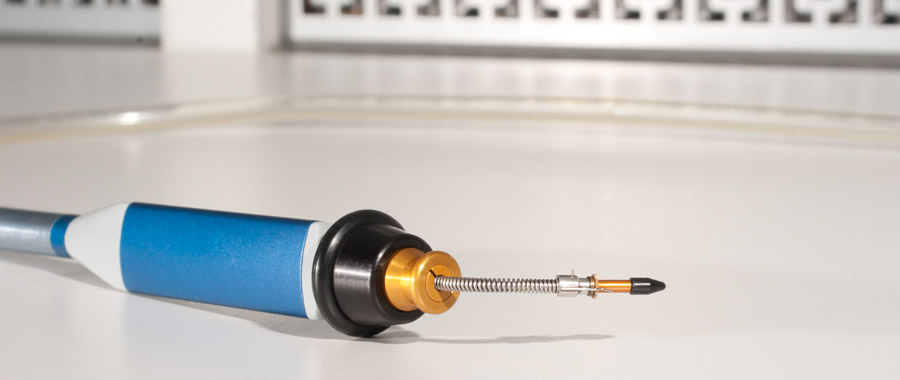

From standard to premium IOL lenses, we are at the forefront of technology and experience to satisfy your manufacturing needs. We are capable of manufacturing most anything as it relates to small plastic or molded lenses, and can even help in the design process if desired.

We are often posed with new and never before seen challenges by our customers. Helping to solve these challenges while advancing vision technology can be difficult, but a joy.

Cleaning and visual inspection

After creating your parts they are brought to one of our clean zones where we run them through our visual inspection and cleaning process. This step is very important as it ensures you will be receiving clean, scratch free parts with every order.

Some of our lens manufacturing capabilities

- Premium & Standard IOL’s

- Specialty contact lenses

- Toric & Atroic lens designs

- Multifocal

- Extended depth of focus (EDOF) lenses

- Freeform & Uncommon optical surfaces

- Lathe cut IOL’s

- Molded IOL’s

- Multi-piece Accommodating lens designs

Commonly handled materials used in ophthalmic devices

Ophthalmic and IOL devices can utilize a plethora of materials at different stages of their development. We are familiar with a great deal of materials, and know the nuances of each as it might relate to your project. For instance, our approach to a hydrophobic material would be different than a hydrophilic material. When it comes to custom formulations often times we have a good idea of where to start.

Non-exhaustive list of materials

- Hydrophilic Acrylics

- Hydrophobic Acrylics

- Custom polymers and hydrogel materials

- Silicone

- Acrylic/Plexiglas (PMMA)

- Polyvinyl chloride (PVC)

- Polycarbonate (PC)

- Polysulphone (PSU)

- Ultem Polyetherimide (PEI)

- Topas Cyclic Olefin Copolymer (COC)

- Nonferrous metals